Surgical blade guards protect medical professionals from accidental injuries and maintain sterility before use. These components must be manufactured with extreme precision, ensuring that the guard closes firmly, does not fail under pressure, and does not introduce contamination. Traditional bonding methods such as glue can weaken over time, introduce chemicals, or compromise sterility.

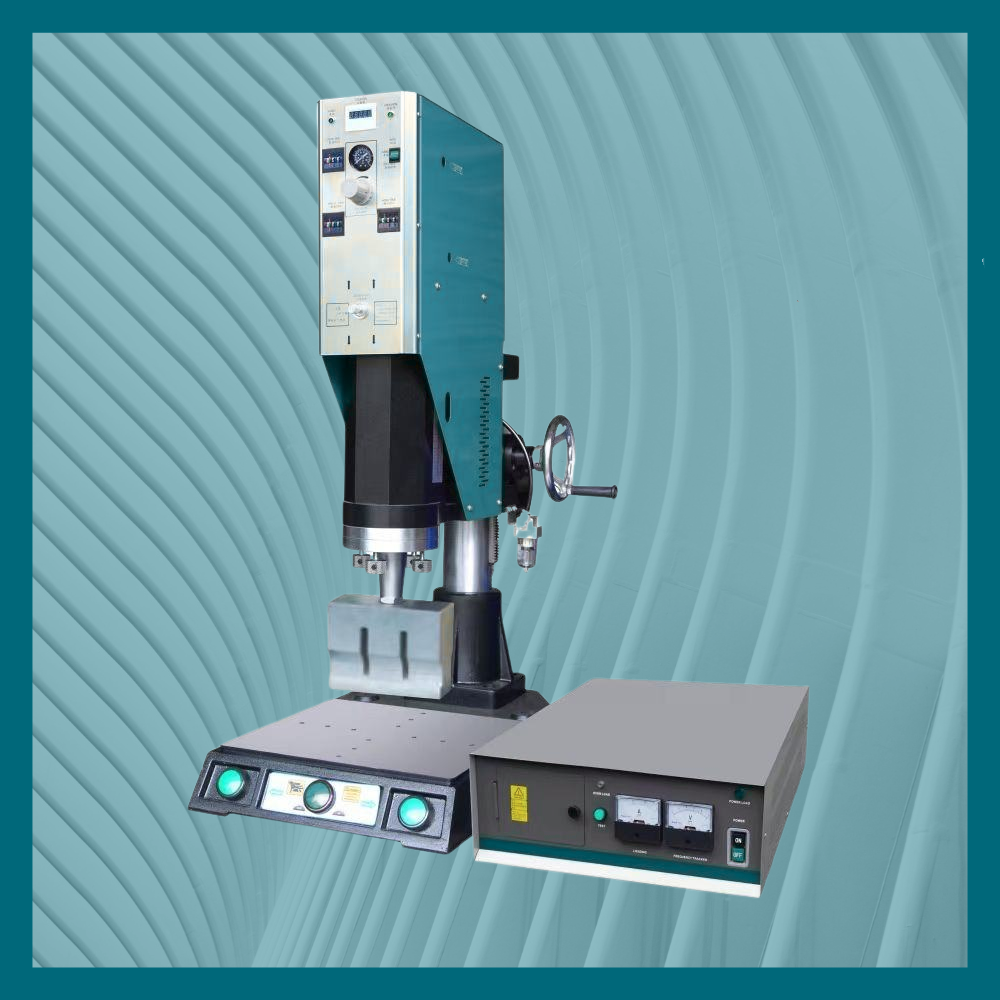

The altrAsonix Ultrasonic Plastic Welding Machine for Surgical Blade Guard Housing solves these challenges by fusing thermoplastic parts using ultrasonic vibrations. This molecular bonding process eliminates adhesives, prevents contamination, and produces welds that meet strict medical safety regulations.

The following guide helps manufacturers understand material behavior, weld joint design, and mechanical factors that influence ultrasonic weld performance for surgical blade protection systems.

Plastic Welding Guide for Surgical Blade Guard Components

Which Plastics Can Be Welded?

Common materials used in blade guard housings include ABS, PP, PC, and reinforced medical-grade thermoplastics. These materials support ultrasonic welding due to their thermoplastic nature.

Elastomers and thermosets are not suitable for ultrasonic welding.

Common Weldable Plastics and Their Behavior

ABS – Provides rigid, accurate welds ideal for safety locking features

PP – Lightweight and chemically stable for sterile assemblies

PC – Transparent and strong for visual inspection-type guards

PE – Flexible but weldable with controlled parameters

PMMA – Clear but brittle

PVC – Limited application due to fumes

Surgical blade guards typically use ABS or PC due to their strength and stability.

Factors Influencing Weld Performance

Melting Temperature

Higher melting materials require more power and amplitude.

Melt Flow Behavior

Smooth melt flow produces stronger and more reliable joints.

Elastic Modulus

Stiffer plastics transmit ultrasonic energy effectively.

Damping Behavior

Controls heat formation and helps prevent part deformation.

Joint Design Recommendations for Blade Guard Housing

Basic Flat Joint

Suitable for simple two-part guard housings.

Step Joint

Ideal for ensuring alignment and tight closing mechanisms.

Tongue and Groove Joint

Prevents unintended opening and enhances sealing.

Mash Joint

Common in thin-walled protective covers.

Joint With Inserted Seal

Used when integrating safety locks or friction-based locking tabs.

Each joint type enhances durability, safety, and sterile performance.

Key Features

• Sterile and airtight welding for surgical blade guards

• Ideal for ABS, PP, PC and medical-grade polymers

• No adhesive contamination or chemical residue

• Precision assembly for locking and safety features

• Long-life aluminium horn for stable welding

• Fast production cycles with consistent results

• Suitable for clean-room and controlled manufacturing environments

• Designed for complex protection-cover geometries

Technical Specifications

(Blade guard housings are medium-sized rigid ABS/PC components → 15 kHz / 2600W Analog recommended)

| Parameter | Details |

|---|---|

| Model | UPM-15K-2600W-ANALOG |

| Frequency | 15 kHz |

| Power Output | 2600W |

| Welding Mode | Time / Manual |

| Rectifier Type | Analog |

| Input Voltage | AC 220V |

| Operation Type | Automatic / Manual |

| Weight | Approx. 110 kg |

| Used For | Medium ABS/PC surgical blade guard housings |

Material Compatibility

| Material | Compatible | Notes |

|---|---|---|

| ABS | Yes | Best for rigid locking features |

| PP | Yes | Good for lightweight covers |

| PC | Yes | High-strength safety housings |

| PE | Yes | Requires controlled welding conditions |

| PVC | Limited | Fumes need control |

| PA | No | Not suitable |

| POM | No | Not weldable |

| PMMA | Partial | Prone to cracking |

Detailed Product Applications

The altrAsonix Ultrasonic Plastic Welding Machine for Surgical Blade Guard Housing is ideal for producing:

• Surgical scalpel blade guards

• Protective covers for disposable scalpels

• Blade safety-lock housings

• Medical sharps protection caps

• Sterile cutting blade enclosures

• Transparent inspection-type blade guards

• Reusable blade protection components

These components must remain sealed, strong, and absolutely clean—ultrasonic welding ensures 100% reliability.

Reviews

There are no reviews yet.