Blood collection devices are used in hospitals, laboratories, diagnostic centers and emergency healthcare settings. They must withstand internal pressure, prevent contamination and maintain airtight integrity. Traditional joining processes, such as gluing and heat sealing, can introduce impurities or compromise structural strength.

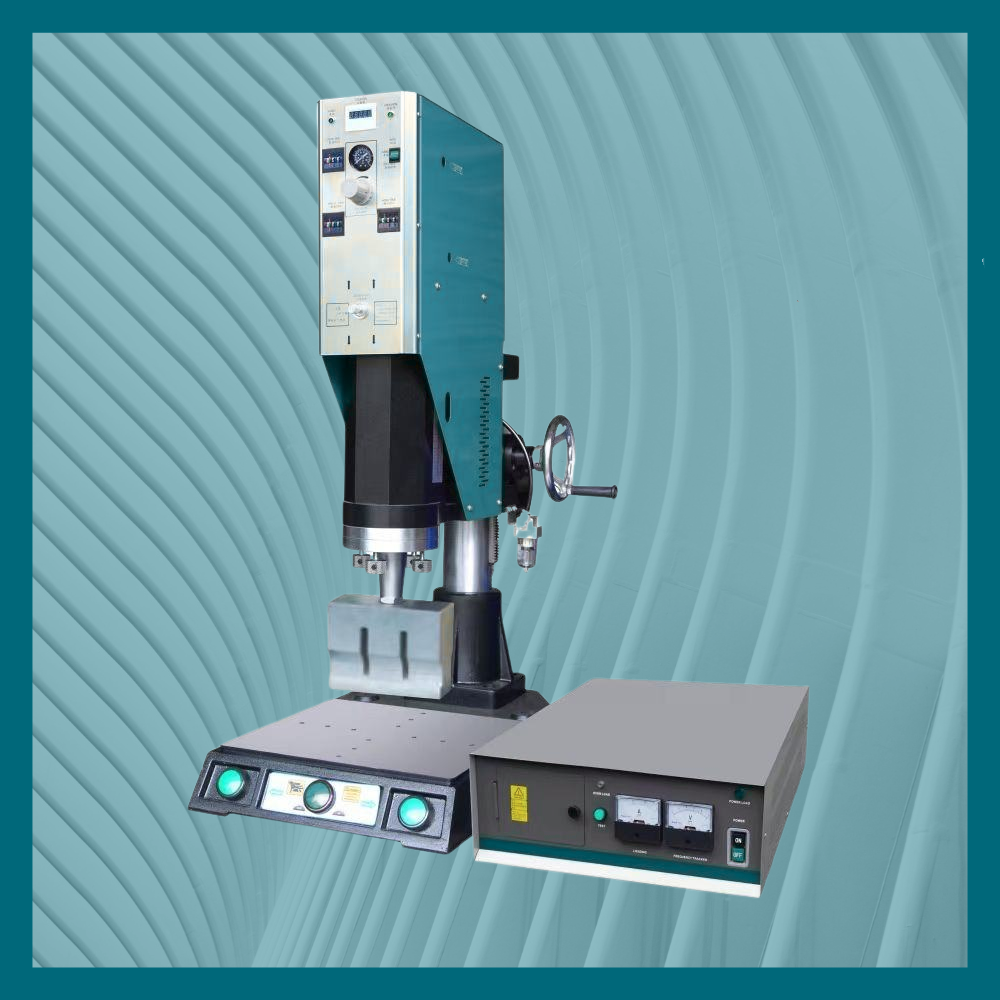

The altrAsonix Ultrasonic Plastic Welding Machine for Blood Collection Device uses high-frequency vibration to melt and bond thermoplastic contact surfaces, producing a uniform and perfectly sealed weld. This method ensures particle-free assembly, high mechanical strength, and complete hermetic sealing—critical for vacuum tubes and blood sampling systems.

To help manufacturers select the right material and process parameters, the following welding guide explains material behavior, joint design and mechanical considerations specific to blood collection device production.

Plastic Welding Guide for Blood Collection Components

Which Plastics Can Be Welded?

Only thermoplastics can be welded using ultrasonic energy. Blood collection devices are primarily made from PP, ABS, PC and PET-based medical polymers.

Elastomers and thermosets cannot create permanent welds due to their chemical behavior under heat.

Common Weldable Plastics and Their Behavior

ABS – Excellent weld strength and dimensional stability

PP – Preferred for blood caps and vial bodies due to chemical resistance

PC – Offers strong, transparent joints for high-pressure devices

PE – Welds with controlled energy settings

PMMA – Clear but brittle

PVC – Requires ventilation control

Most blood collection devices use PP and ABS for high repeatability during ultrasonic fusion.

Factors Influencing Weld Performance

Melting Temperature

Higher melting plastics require more weld energy.

Melt Flow Properties

Better melt flow produces stronger, more consistent joints.

Elastic Modulus

Stiffer plastics transfer more ultrasonic energy to the weld zone.

Damping Characteristics

Materials with controlled damping generate heat at the interface efficiently.

Joint Design Recommendations for Blood Collection Devices

Basic Flat Joint

Useful for simple sterile caps and covers.

Step Joint

Ideal for tubes requiring perfect alignment and visual accuracy.

Tongue and Groove Joint

Maintains tight sealing for vacuum-based blood collection.

Mash Joint

Used for thin shells and micro-sized components.

Joint with Inserted Seal

Appropriate for components including rubber stoppers or sealing rings.

These geometries help create consistent and airtight welds for medical diagnostic systems.

Key Features

• Airtight sealing for vacuum blood tubes and caps

• Zero particulates and no adhesive contamination

• High stability for PP, ABS and PC medical plastics

• Clean-room compatible assembly

• Precise parameter control for micro medical components

• Consistent fusion preventing leakage or pressure loss

• Long-life aluminium horn designed for stable welding performance

• Designed for high-volume blood collection device production

Technical Specifications

(Blood collection devices include small, thin PP/ABS parts → 20 kHz / 2000W Analog recommended)

| Parameter | Details |

|---|---|

| Model | UPM-20K-2000W-ANALOG |

| Frequency | 20 kHz |

| Power Output | 2000W |

| Welding Mode | Time / Manual |

| Rectifier Type | Analog |

| Input Voltage | AC 220V |

| Operation Type | Manual |

| Weight | Approx. 90 kg |

| Used For | Small PP/ABS blood collection components requiring airtight welding |

Material Compatibility

| Material | Compatible | Notes |

|---|---|---|

| PP | Yes | Most common for blood caps |

| ABS | Yes | Stable weld structure |

| PC | Yes | Transparent diagnostic parts |

| PE | Yes | Requires controlled weld time |

| PVC | Limited | Requires exhaust control |

| PA | No | Not suitable |

| POM | No | Not weldable |

| PMMA | Partial | Brittle in pressure applications |

Detailed Product Applications

The altrAsonix Ultrasonic Plastic Welding Machine for Blood Collection Device is used for:

• Blood tube caps and closures

• Vacuum blood collection tube bodies

• Luer lock connectors

• Needle shield components

• Vial sealing covers

• Diagnostic cartridge housings

• Microfluidic plastic parts

• Sample chamber enclosures

Each of these components must remain airtight to preserve sample purity, making ultrasonic welding the ideal joining technique.

Reviews

There are no reviews yet.