Nebulizers are essential respiratory devices used in hospitals, clinics and home-care environments to deliver aerosolized medication to patients. The plastic body of a nebulizer must be durable, airtight and precisely aligned to ensure correct airflow and dosage accuracy. Any leakage or structural mismatch can compromise the efficiency of the treatment.

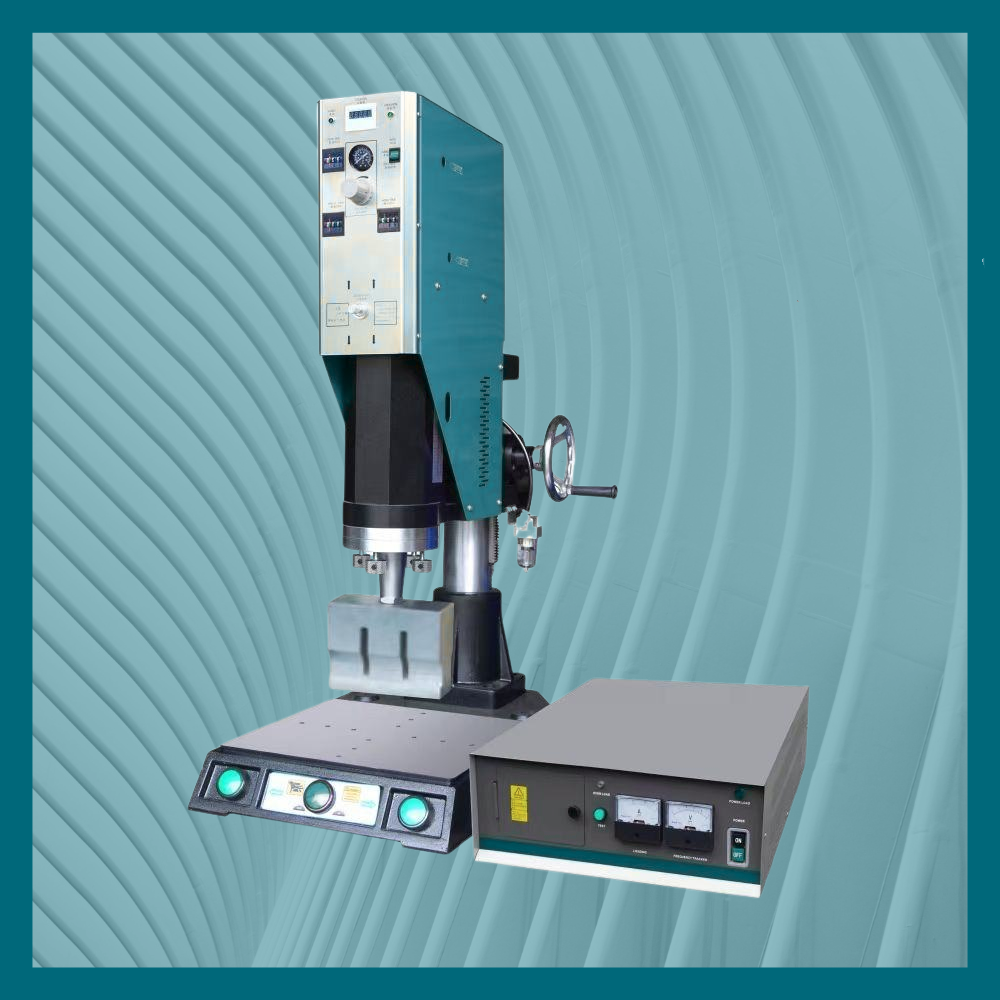

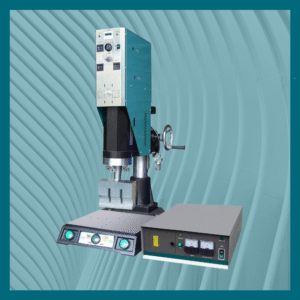

The altrAsonix Ultrasonic Plastic Welding Machine for Nebulizer Body provides a perfect solution by using ultrasonic energy to fuse thermoplastic components at the molecular level. This process ensures zero contamination, uniform weld strength and consistent sealing across production cycles.

Unlike solvent bonding or mechanical fastening, ultrasonic welding eliminates chemical exposure and prevents structural stress, making it ideal for medical devices requiring high sterility and biocompatibility.

The following technical guide helps manufacturers understand material selection, weld-joint design and critical welding behaviors for nebulizer assemblies.

Plastic Welding Guide for Nebulizer Assemblies

Which Plastics Can Be Welded?

Nebulizer bodies are typically manufactured from PP, ABS, PC and clear polymers that melt and re-solidify cleanly under ultrasonic energy. These plastics ensure biocompatibility and withstand exposure to medications and moisture.

Elastomers cannot be welded because they deform and return to shape instead of melting.

Thermosets degrade under heat and cannot form molecular welds.

Common Weldable Plastics and Their Behavior

ABS – Strong structural welds with dimensional accuracy

PP – Lightweight and suitable for medication cups and flow channels

PC – Transparent housings with excellent weld strength

PE – Soft but weldable with controlled pressure

PMMA – Clear but brittle under respiratory pressure

PVC – Conditional welding due to fumes

Nebulizer housings typically use PP or PC, as both demonstrate ideal melt behavior for ultrasonic welding.

Factors Influencing Weld Strength

Melting Temperature

Determines amplitude and weld-cycle requirements.

Flow Characteristics

A uniform melt promotes hermetic sealing and structural stability.

Elastic Modulus

The stiffer the plastic, the more efficiently it transfers ultrasonic energy.

Damping Behavior

Controls heat buildup at the weld interface, essential for narrow air channels in nebulizers.

Joint Design Techniques for Nebulizer Components

Basic Flat Joint

Useful for outer covers and medication chamber caps.

Step Joint

Self-aligning; ideal for multi-part nebulizer housings.

Tongue and Groove Joint

Ensures airtight sealing of inhalation flow channels.

Mash Joint

Perfect for thin-walled mouthpiece components.

Joint With Inserted Seal

Used for nebulizer designs that include valves or O-rings inside.

Each geometry ensures minimal leakage and consistent airflow delivery.

Key Features

• Airtight and contamination-free welding for nebulizer housings

• Perfect for PP, ABS, PC and transparent medical plastics

• Zero adhesive usage for improved sterility

• Clean-room compatible assembly process

• High accuracy and stable weld performance

• Long-life aluminium ultrasound horn designed for medical-grade use

• Fast, repeatable welding cycles for mass production

• Designed for complex respiratory component shapes

Technical Specifications

(Nebulizer bodies are medium-sized PP/PC components → 15 kHz / 2600W Analog recommended)

| Parameter | Details |

|---|---|

| Model | UPM-15K-2600W-ANALOG |

| Frequency | 15 kHz |

| Power Output | 2600W |

| Welding Mode | Time / Manual |

| Rectifier Type | Analog |

| Input Voltage | AC 220V |

| Operation Type | Automatic / Manual |

| Weight | Approx. 110 kg |

| Used For | Medium PP/PC nebulizer housings and respiratory plastic assemblies |

Material Compatibility

| Material | Compatible | Notes |

|---|---|---|

| PP | Yes | Primary material for nebulizer chambers |

| ABS | Yes | Ensures rigid housing structure |

| PC | Yes | Transparent nebulizer bodies |

| PE | Yes | Limited use for small parts |

| PVC | Limited | Requires special ventilation |

| PA | No | Not suitable |

| POM | No | Not weldable |

| PMMA | Partial | Brittle material under pressure |

Detailed Product Applications

The altrAsonix Ultrasonic Plastic Welding Machine for Nebulizer Body is ideal for manufacturing:

• Nebulizer main housings

• Medication cup assemblies

• Mouthpiece cover plastic parts

• Airflow channels and connectors

• Inhalation chambers

• Oxygen therapy attachment components

• Atomizer cap assemblies

• Pediatric nebulizer parts

These components require clean and airtight fusion to ensure safe respiratory performance.

Reviews

There are no reviews yet.